Control system functions:

Basic functions: start-stop control, air-fuel ratio control;

Measurement protection: all unit parameters including cylinder temperature and exhaust temperature are measured, and engine protection is complete;

Industrial control adaptation: control of all working conditions, including idle speed control, low load control, etc.

Power management: flexible control of power generation;

Network function: easy to build a large automatic power station, effectively improve the level of network management;

Safety protection: the separation of strong and weak electricity is realized.

Local monitoring cabinet:

Including large ECU system, generator set controller IG-NTC, signal acquisition module, electronic speed regulation, display, DC power supply, etc., the unit control functions are all centralized in the cabinet. Each unit is equipped with one local monitoring cabinet, which is placed on the side of the unit.

-- Unit start, speed regulation, automatic grid connection, power factor control, load loading and load shedding;

-- Power measurement and display: U, I, Hz, kW, kVAr, kVA, PF, kWh, kVAhr;

-- Alarm and protection: overload/short circuit, over voltage/under voltage, over frequency/under frequency, reverse power, high winding temperature, overspeed, etc.

-- Collect various parameters of the unit: such as cylinder temperature, exhaust temperature, oil temperature, water temperature, oil pressure, speed, gas regulating valve opening, etc.

Unit circuit breaker cabinet:

Main switch selection of domestic top brand circuit breaker, with undercalender protection and line current four-stage protection: overload long delay, short circuit short delay, short circuit instantaneous and ground fault current protection.

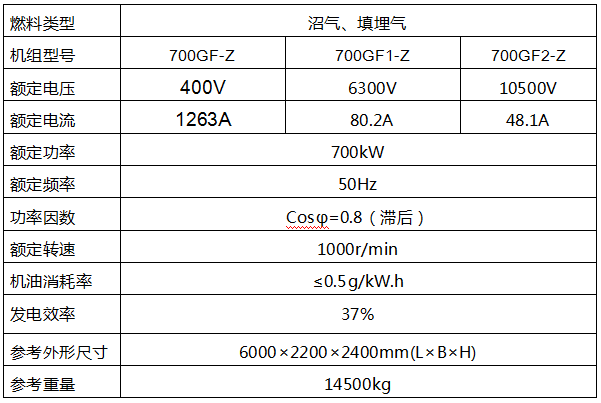

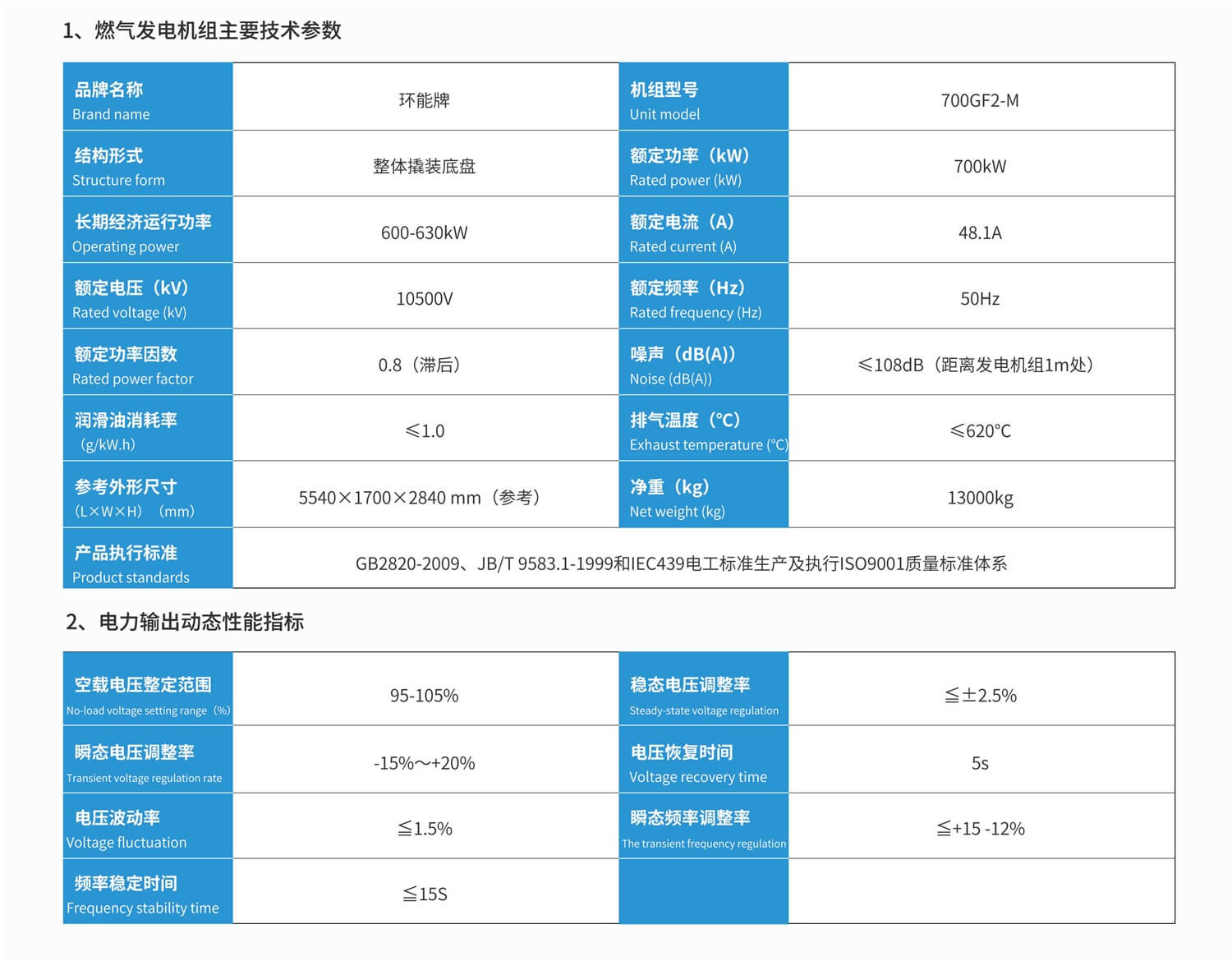

Basic parameters

Basic parameters

FEATURES

FEATURES

advantage

advantage

Tel:0531-69953988

Tel:0531-69953988  Add:101, Building 5, Liandong U Valley Science and Technology Innovation Center, Zhangjin Comprehensive Bonded Zone, No. 33688 Jingshi East Road, Suncun Street, Jinan Area, China (Shandong) Pilot Free Trade Zone

Add:101, Building 5, Liandong U Valley Science and Technology Innovation Center, Zhangjin Comprehensive Bonded Zone, No. 33688 Jingshi East Road, Suncun Street, Jinan Area, China (Shandong) Pilot Free Trade Zone