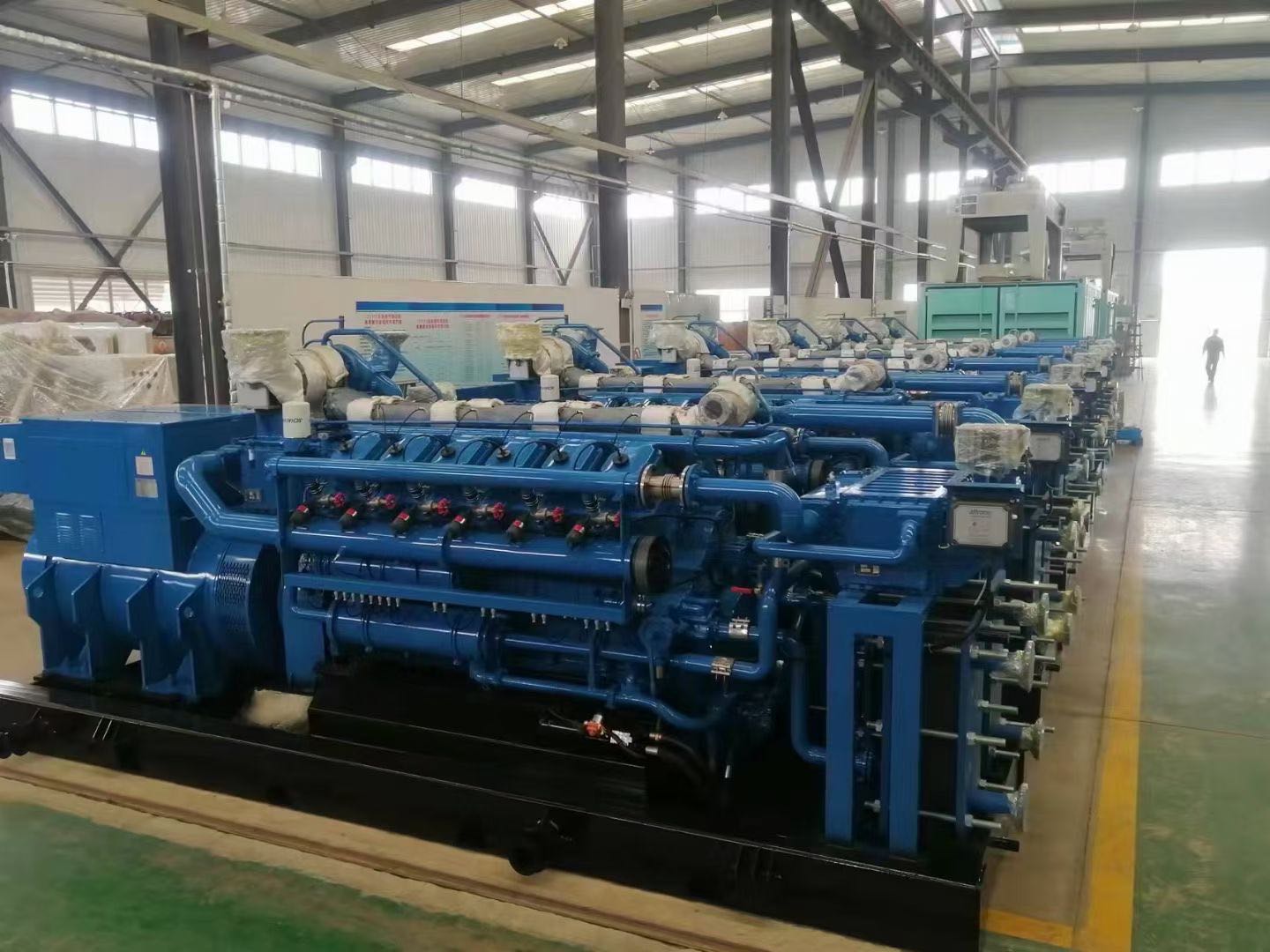

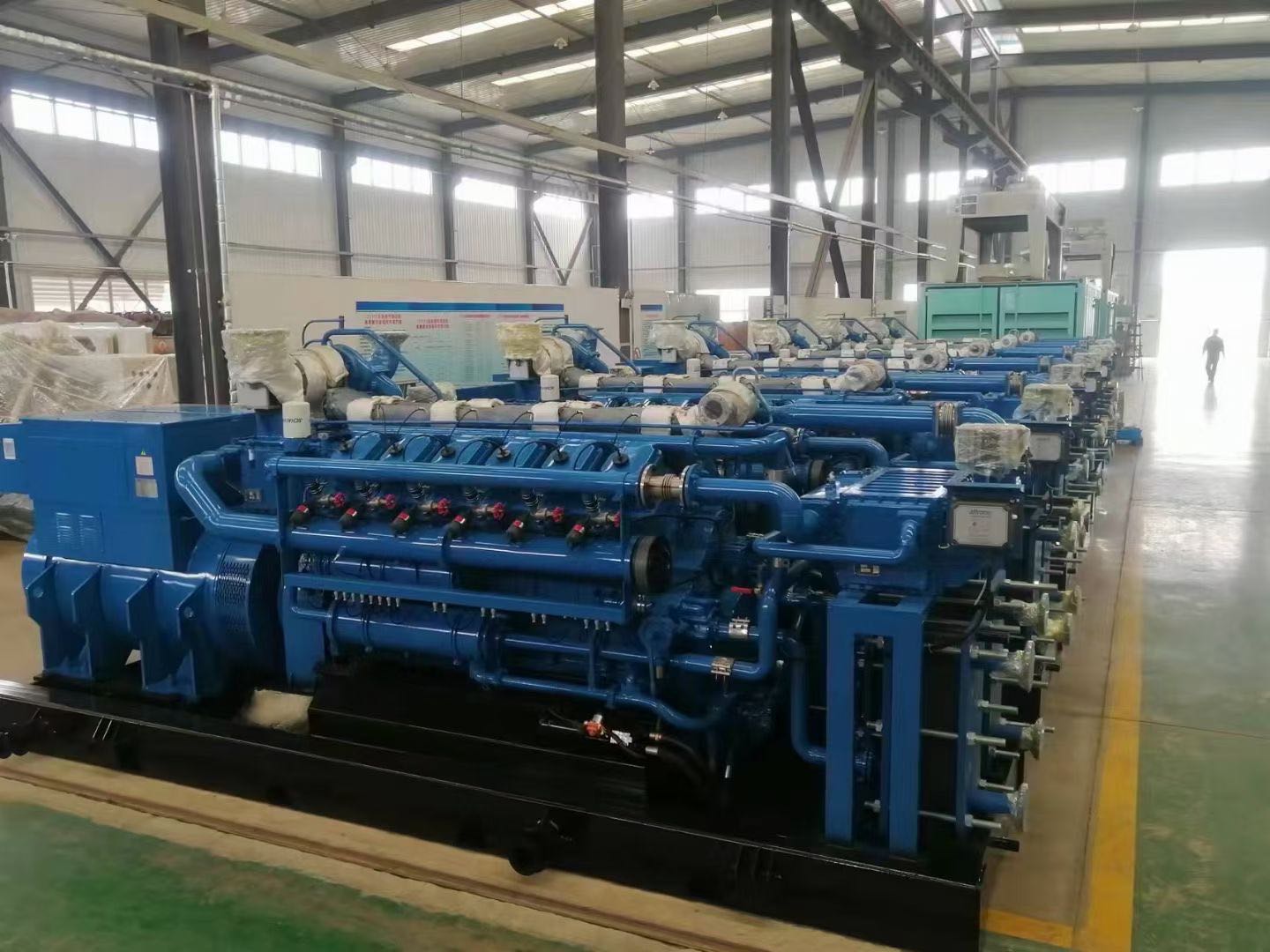

在工业生产过程中产生的大量电石气等工业尾气比较稳定,如果能将这些尾气进行有效利用,就能减少生产企业能源消耗或者高昂的工业用电成本,在当前的环保大趋势下也是个非常不错的选择,其电能可以被用作本厂区的设备用电,也可以作为备用电能储存起来或者办公区域用电。目前在发电方面以小电量发电为主,但随着企业规模的不断发展,产生的驰放气的量增加,同时在燃烧方面的改进以及燃气轮机发电效率的提高,将会使驰放气在发电方面也会有着更广泛的应用。

The large amount of industrial exhaust gas, such as calcium carbide gas, generated in the industrial production process is relatively stable. If these exhaust gases can be effectively utilized, it can reduce energy consumption or high industrial electricity costs for production enterprises. In the current trend of environmental protection, it is also a very good choice. Its electricity can be used for equipment in the factory area, as well as for backup energy storage or office area electricity. At present, small electricity generation is the main focus in power generation. However, with the continuous development of enterprise scale, the amount of exhaust gas generated increases. At the same time, improvements in combustion and the improvement of gas turbine power generation efficiency will make exhaust gas more widely used in power generation.

由此可见,电石气作为一种清洁能源用来发电,既能够节省成本,又可以减少污染,对企业来说无疑是一大利好。但对于驰放气发电后排放的尾气还需要做进一步的处理,才能达到环保标准。为此,陕西一家利用驰放气发电的公司从我公司订制了一套驰放气发电机组烟气脱硝系统来对机组尾气中的NOX进行处理,并实现了达标排放。下面我们就来看下这套系统的基本原理和特点。

From this, it can be seen that calcium carbide gas, as a clean energy source used for power generation, can save costs and reduce pollution, which is undoubtedly a great benefit for enterprises. However, further treatment is needed to meet environmental standards for the exhaust emissions from the power generation of the exhaust gas. Therefore, a company in Shaanxi that utilizes exhaust gas to generate electricity has customized a set of exhaust gas denitrification system for exhaust gas generation units from our company to treat NOX in the unit's exhaust gas and achieve standard emissions. Let's take a look at the basic principles and characteristics of this system.

工业尾气脱硝系统采用SCR(Selective Catalytic Reduction)技术路线对NOX进行处理,其在一定温度(一般为250℃-450℃)段,在催化剂的作用下可将氮氧化物(NOx)分解成无害的氮气(N2)和水(H2O),目前由我司设计制作的系列SCR脱硝系统已在多个领域的众多项目中成功应用。

The industrial tail gas denitrification system adopts the SCR (Selective Catalyst Reduction) technology route to treat NOX. At a certain temperature range (usually 250 ℃ -450 ℃), under the action of a catalyst, nitrogen oxides (NOx) can be decomposed into harmless nitrogen (N2) and water (H2O). Currently, the series of SCR denitrification systems designed and manufactured by our company have been successfully applied in many projects in multiple fields.

工业尾气脱硝系统具有体积小、结构简单、运行方便可靠、系统运行阻力小、自动化程度和脱硝效率高、无二次污染且耐腐蚀性强,整体性能优良,一次投资和运行费用相对较低等特点,一经投入使用,便得到了客户的充分肯定。

The industrial tail gas denitrification system has the characteristics of small size, simple structure, convenient and reliable operation, low system operation resistance, high automation and denitrification efficiency, no secondary pollution, strong corrosion resistance, excellent overall performance, relatively low primary investment and operating costs. Once put into use, it has been fully recognized by customers.

工业尾气SCR烟气脱硝系统性能指标:

Performance indicators of industrial exhaust SCR flue gas denitrification system:

高效,去除率可达95%以上,可保证项目氮氧化物去除效果;

Efficient, with a removal rate of over 95%, which can ensure the nitrogen oxide removal effect of the project;

催化剂活性温度300-580℃;

Catalyst activity temperature 300-580 ℃;

采用蜂窝状高空速催化剂,比表面积大,体积紧凑;

Adopting honeycomb shaped high airspeed catalyst, with a large specific surface area and compact volume;

烟气脱硝系统氨逃逸控制在2.5mg/Nm3以下;

The ammonia escape of the flue gas denitrification system should be controlled below 2.5mg/Nm3;

整个设备温度损失3℃以内,满足脱硝和后方余热装置的使用;

The temperature loss of the entire equipment is within 3 ℃, meeting the requirements for the use of denitrification and rear waste heat devices;

烟气脱硝系统的整体阻力不影响烟气的正常排出;

The overall resistance of the flue gas denitrification system does not affect the normal discharge of flue gas;

脱硝系统结构简单、无副产物、运行方便、可靠性高、一次投资相对较低;

The denitrification system has a simple structure, no by-products, convenient operation, high reliability, and relatively low one-time investment;

自动化程度高,可靠性好;

High degree of automation and good reliability;

该系统组合小巧,连接简约快捷,耐腐蚀性强,整体性能优良。

The system has a compact combination, simple and fast connection, strong corrosion resistance, and excellent overall performance.

本文的精彩内容由

工业尾气发电机组提供知识提供,本网站还有很多的精彩内容,更多的内容您可以点击进入:

我们有专门的客服为您解答问题

The exciting content of this article is provided by the knowledge of industrial exhaust gas generator sets. There are also many exciting content on this website, and you can click to enter more content: We have dedicated customer service to answer your questions

联系 - 热线

联系 - 热线

联系 - 热线

联系 - 热线