At present, the most widely used fields of biomass gasification in China are centralized gas supply and small and medium-sized gasification power generation, and a small amount is used for industrial boiler heating. The rural centralized gas supply project solves the problems of crop straw burning and cooking energy consumption, while biomass gasification power generation is mainly aimed at industrial enterprises such as wood processing plants and rice mills with a large amount of biomass waste. Straw gasification in China is mainly used for heating, gas supply, power generation and chemical synthesis.

(1) Straw gasification heating. Straw gasification heating refers to that the gas generated after straw gasification in the gasifier is sent to the next burner for combustion to provide heat energy for end users. Straw gasification heating technology is widely used in regional heating and drying of agricultural and sideline products such as wood and grain. Compared with conventional wood drying technology, it has the advantages of fast heating, strong firepower and good drying quality, and can shorten drying cycle and reduce costs.

(2) Straw gasification gas supply. Straw gasification gas supply means that the biomass gas produced by the gasifier provides cooking gas for residents through corresponding supporting equipment. Straw gasification gas supply can be divided into centralized gas supply and separate gas supply.

① Straw gasification and centralized gas supply. Biomass gasification centralized gas supply system is a new biomass energy utilization technology developed in China since the 1990s. It is to set up a biomass gasification station in a village or group in the countryside, convert the biomass into gas after gasification in the gasifier, and transmit and distribute it to users through the gas transmission network. The system scale is generally from tens to hundreds of households. At present, China has widely promoted the use of biomass gasification technology to build a centralized gas supply system to meet the needs of rural residents for cooking and heating.

In the straw gasification centralized gas supply system, the selection of gasifier is determined according to different gas consumption scale. If the number of gas supply households is small, fixed bed gasifier is selected; If there are many gas supply households (generally more than 1000 households), it is better to use fluidized bed gasifiers. Straw gas stoves are different from ordinary urban gas stoves. There are many domestic manufacturers of such stoves, and the effect is also good, which can meet user requirements.

② Household straw gasification gas supply. This method is used by rural residents from household to household. The household uses a small straw gasifier, and the gas generated is directly used by the stove. The system has the advantages of small size and low investment. However, there are also obvious disadvantages: because the gasifier is directly connected to the stove, the biomass gas has not been purified, so tar seeps from the connecting pipe and the gasifier on the stove, which is very poor in sanitation, and is easy to block the connecting pipe and the stove; Because the gasifier is small, the gasification conditions are not easy to control, and the quality of combustible gas components in the produced gas is unstable and discontinuous, which affects the combustion and even has safety problems; It takes a certain starting time from ignition to gas production, which increases labor time, and flue gas emission during this period is also a problem.

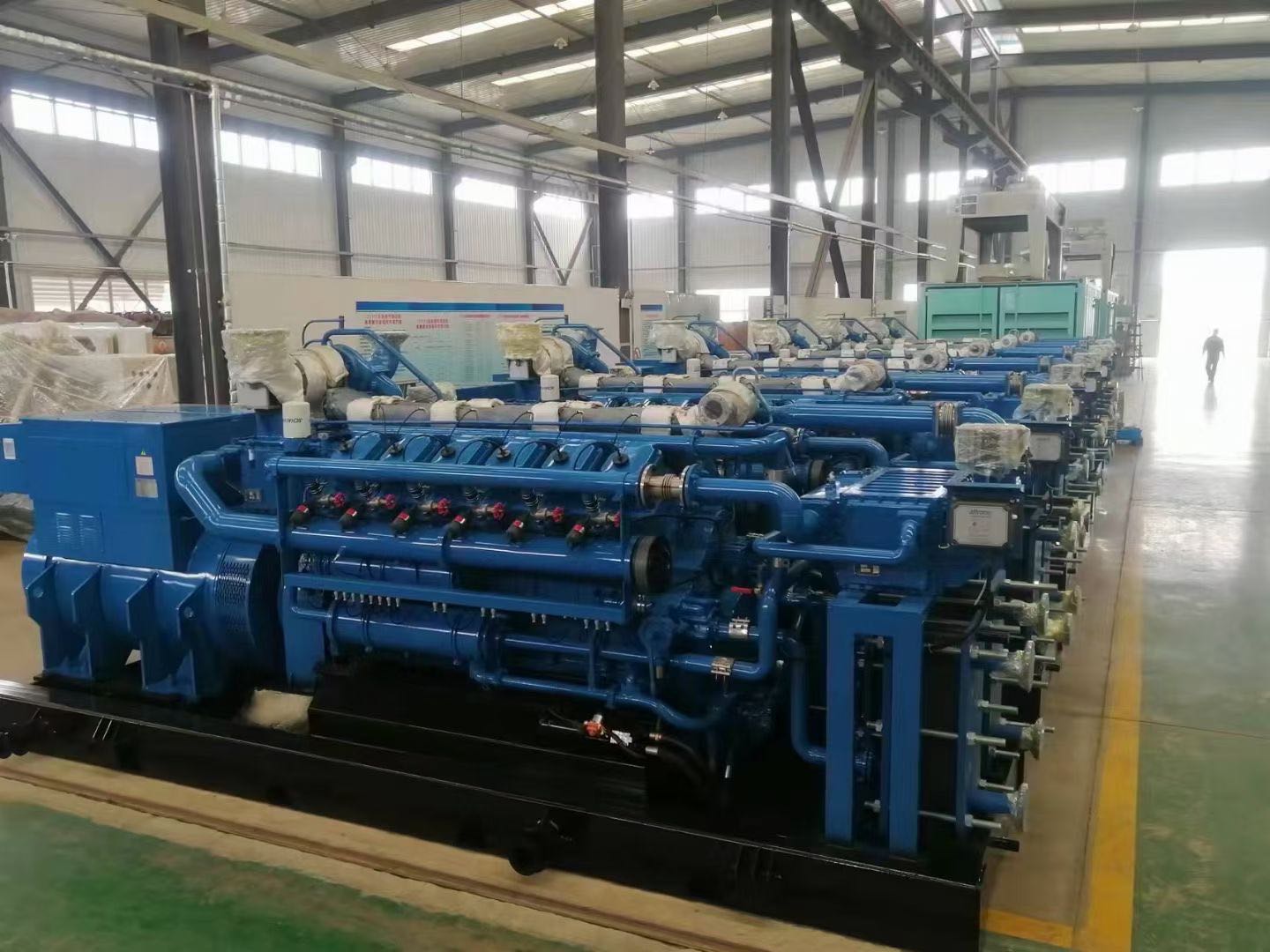

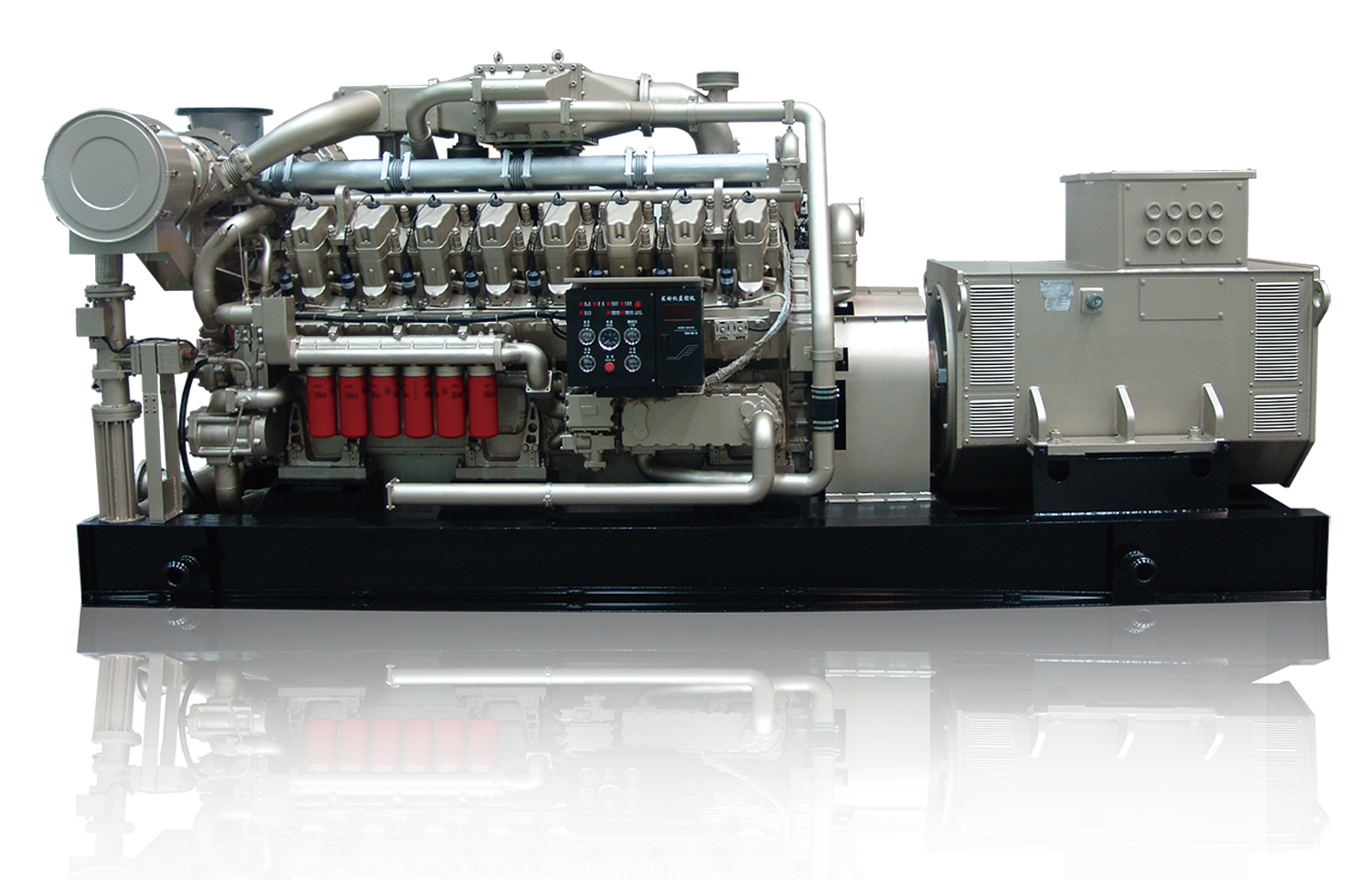

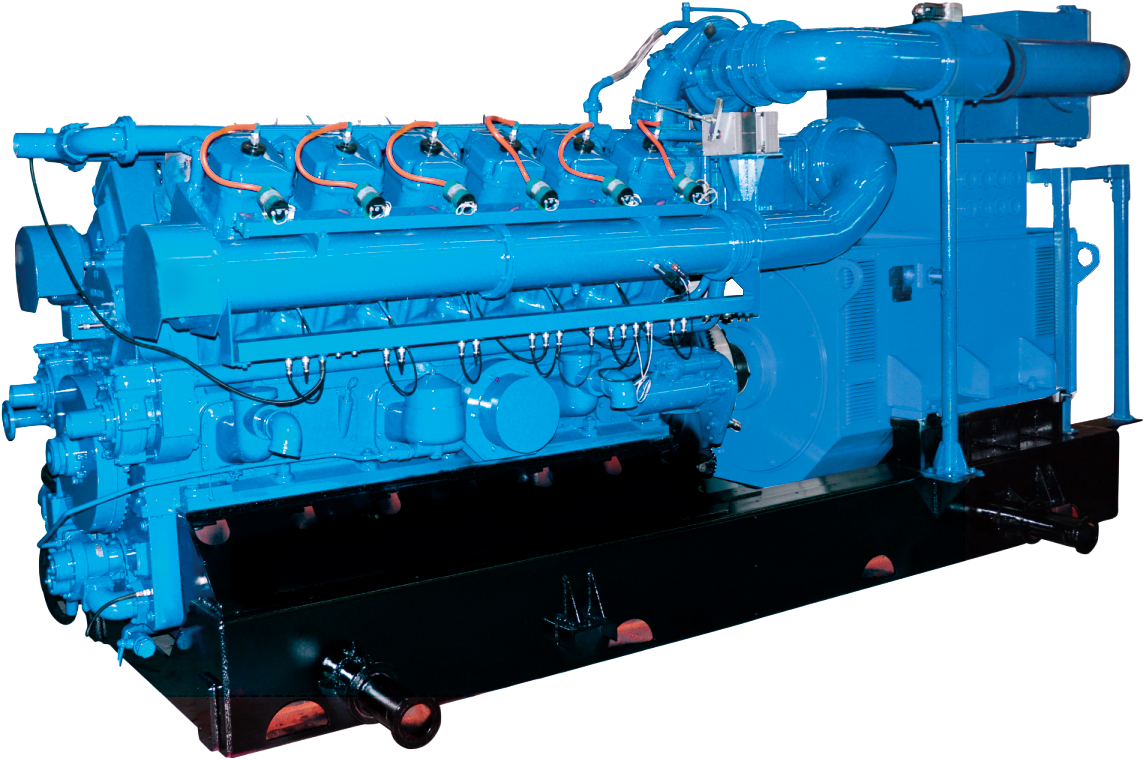

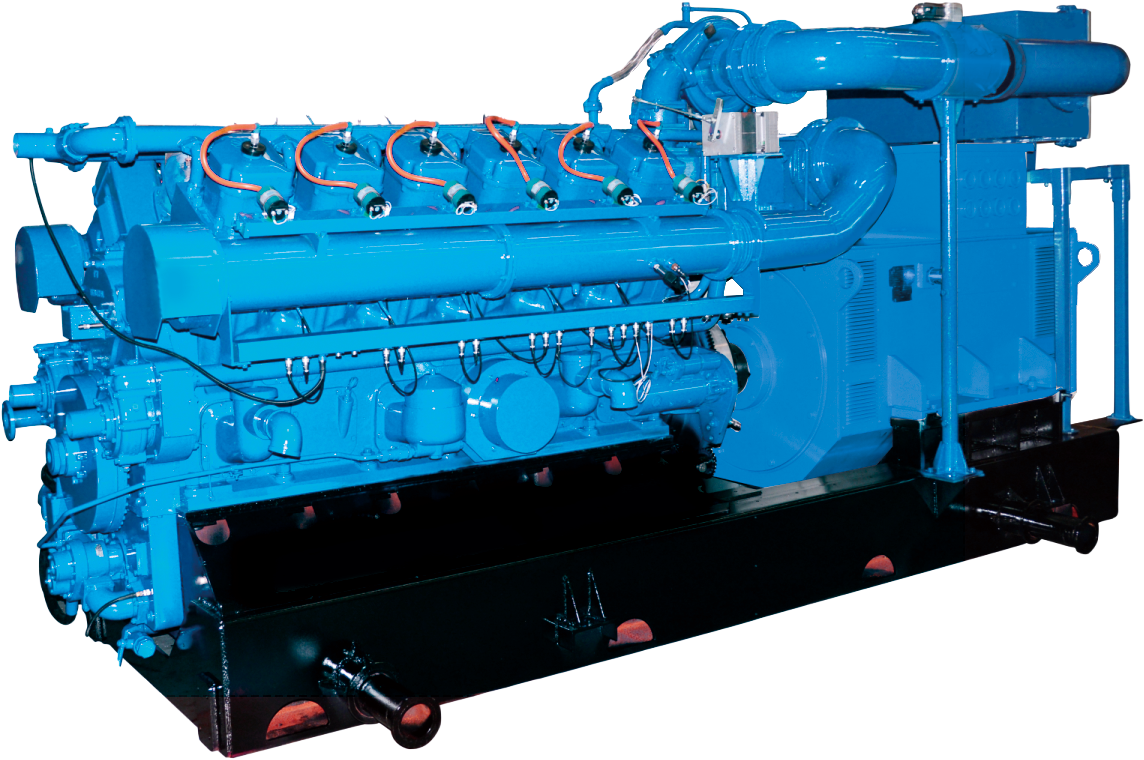

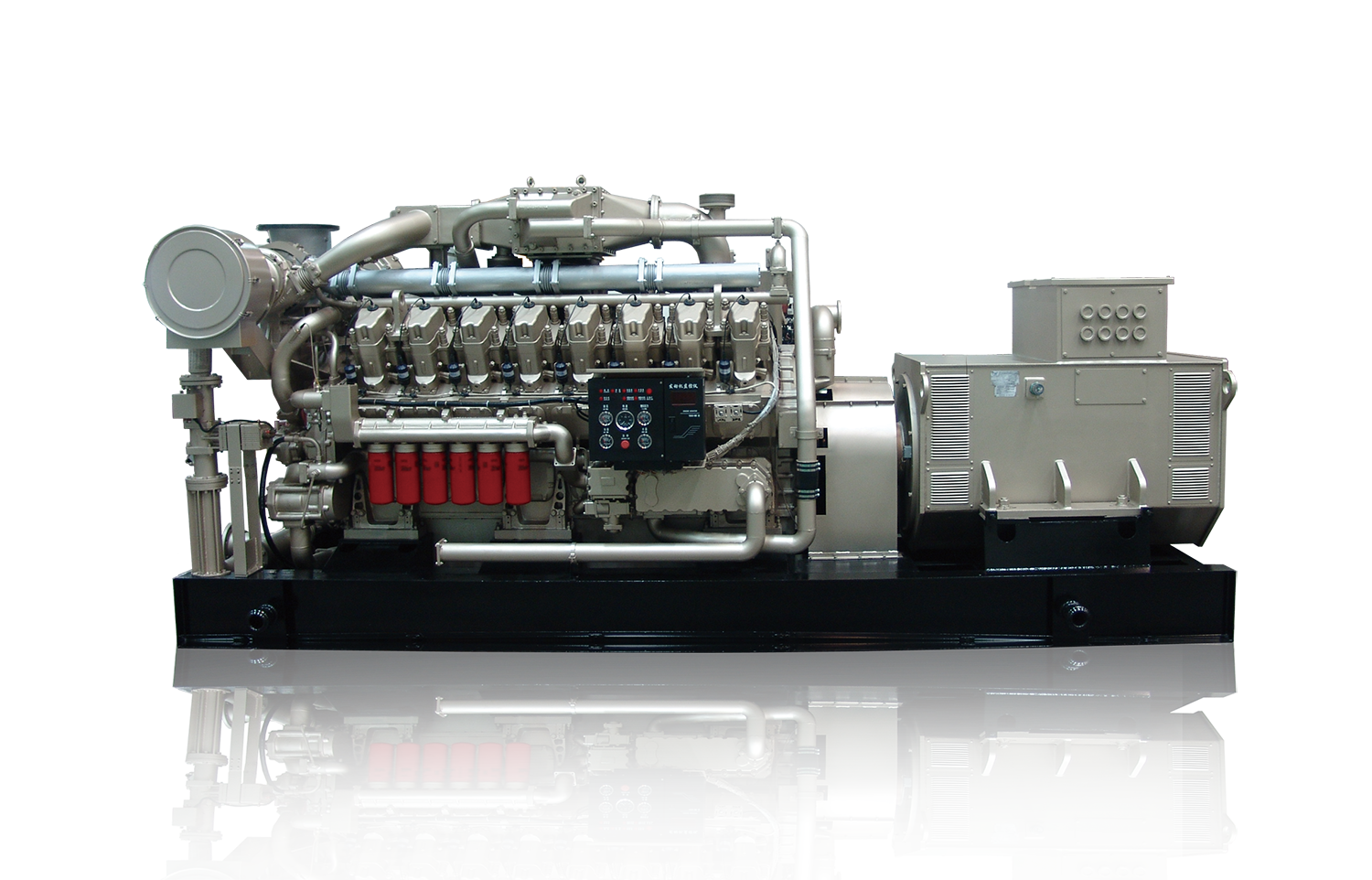

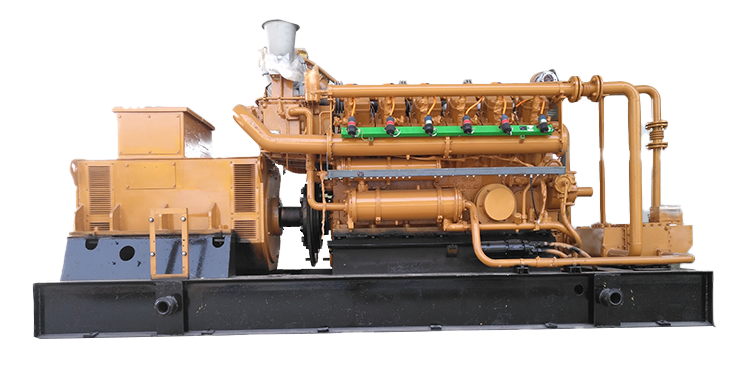

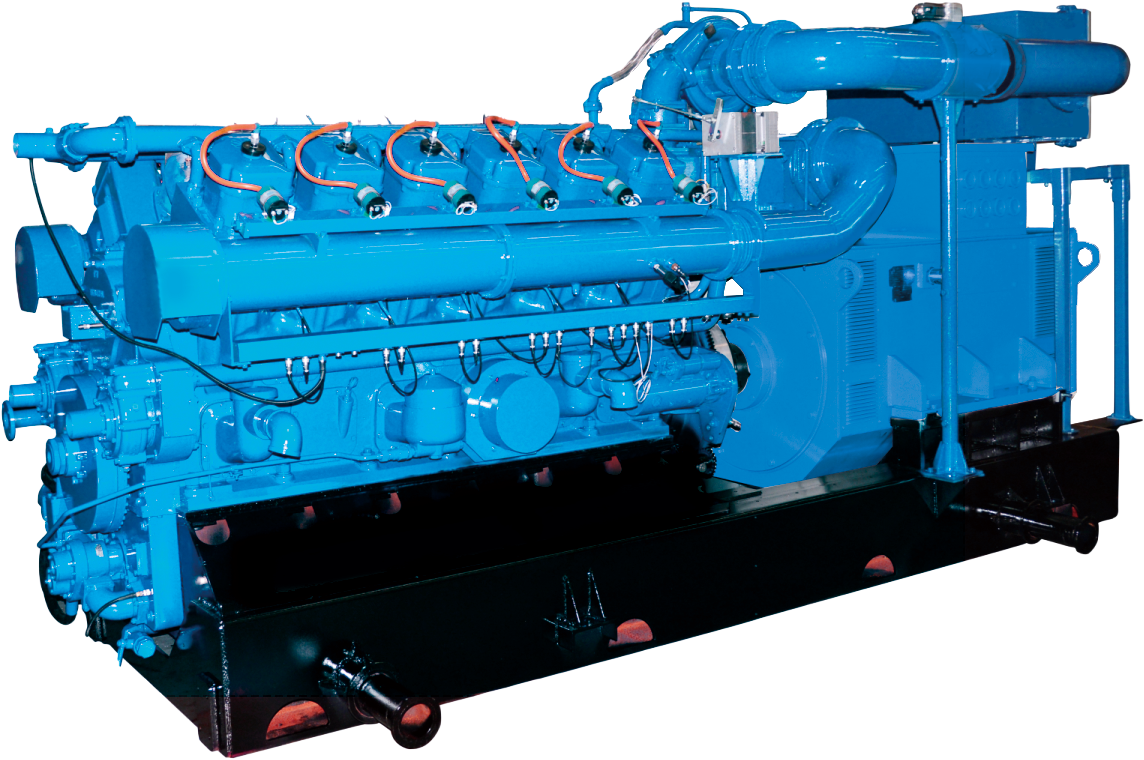

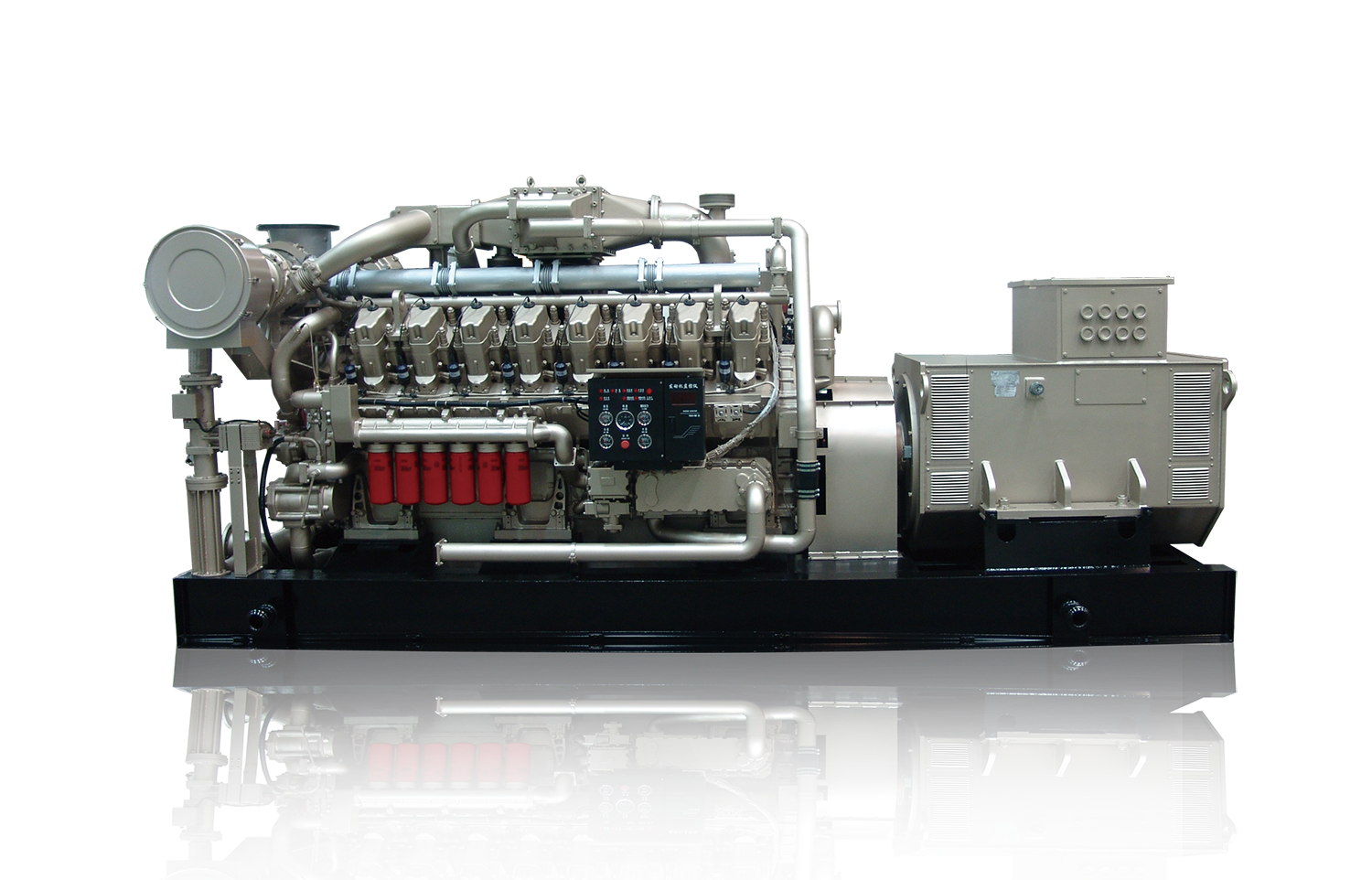

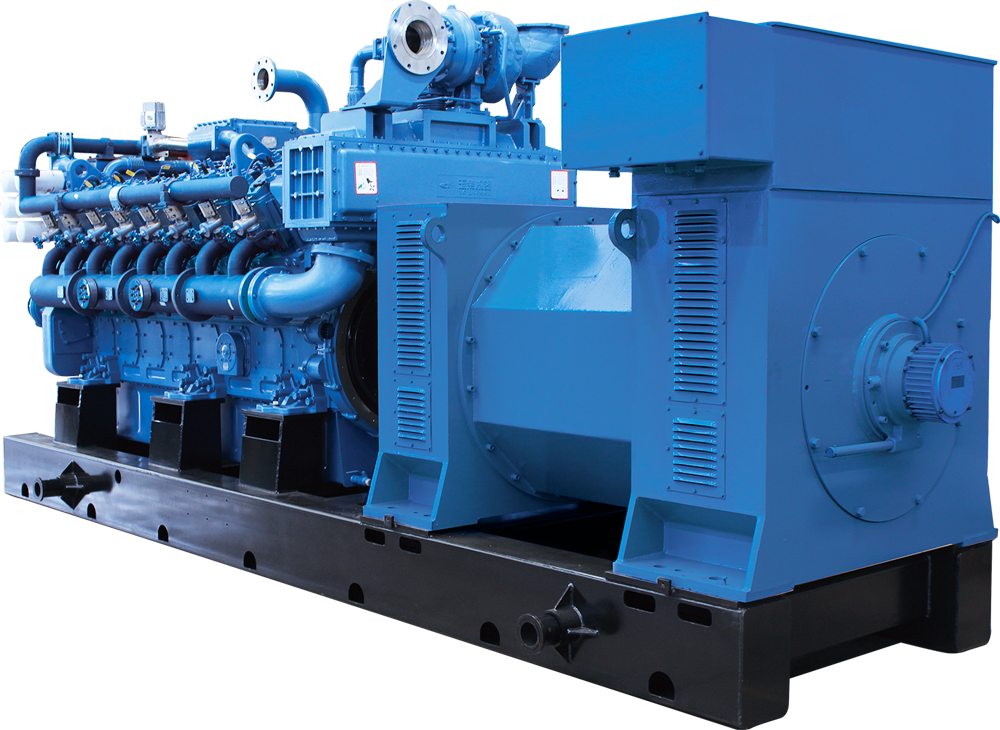

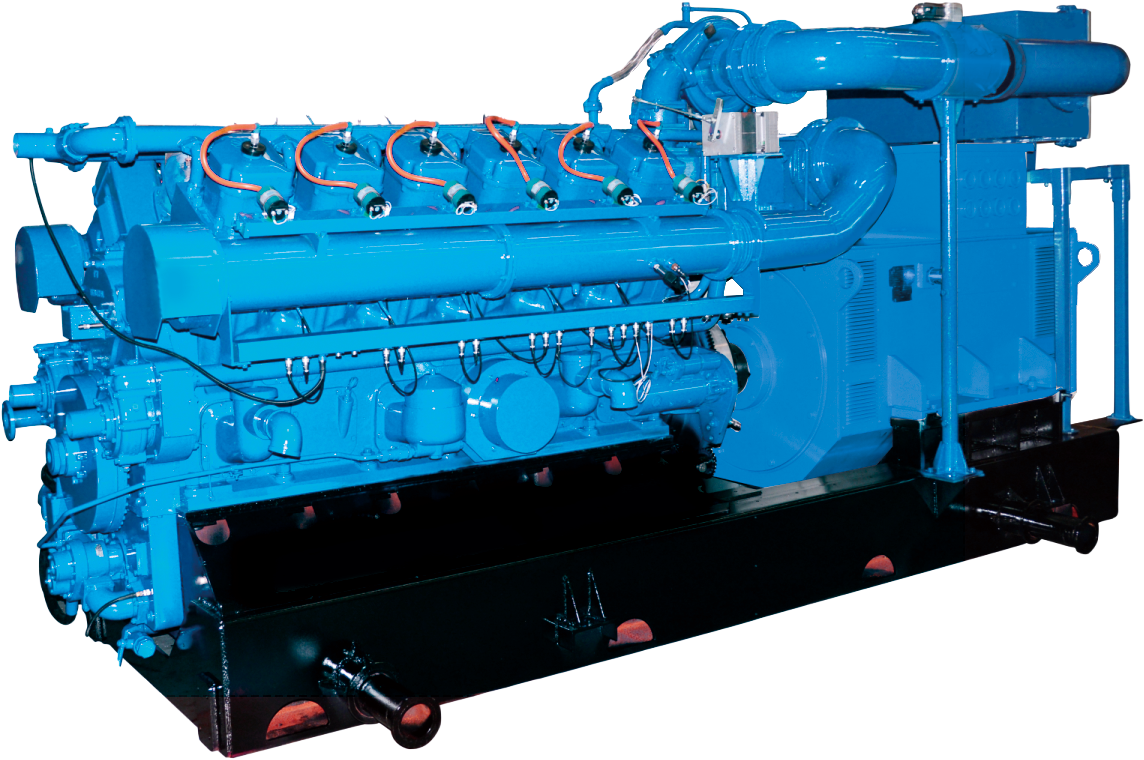

③ Straw gasification for power generation. China has a certain foundation in biomass gasification. As early as the early 1960s, the research work in this field was carried out. In the past 20 years, the further research of biomass gasification power generation technology has been accelerated. The developed small-scale gasification power generation system has the characteristics of low investment, good raw material adaptability and scale flexibility. The power of the successfully developed small-scale biomass gasification power generation equipment has ranged from several thousand watts to 5000 kilowatts.

The structure of gasifier includes layered down-suction gasifier, open-center gasifier, down-suction gasifier and atmospheric circulating fluidized bed gasifier. The single-fuel gas internal combustion engine and dual-fuel internal combustion engine are adopted, and the maximum power of single unit has reached 500 kW.

With the summary above, we hope to help our customers. If you don't understand or need help, please click our website: Or call for consultation, and we will do our best to solve it for you

Tel:0531-69953988

Tel:0531-69953988  Add:101, Building 5, Liandong U Valley Science and Technology Innovation Center, Zhangjin Comprehensive Bonded Zone, No. 33688 Jingshi East Road, Suncun Street, Jinan Area, China (Shandong) Pilot Free Trade Zone

Add:101, Building 5, Liandong U Valley Science and Technology Innovation Center, Zhangjin Comprehensive Bonded Zone, No. 33688 Jingshi East Road, Suncun Street, Jinan Area, China (Shandong) Pilot Free Trade Zone