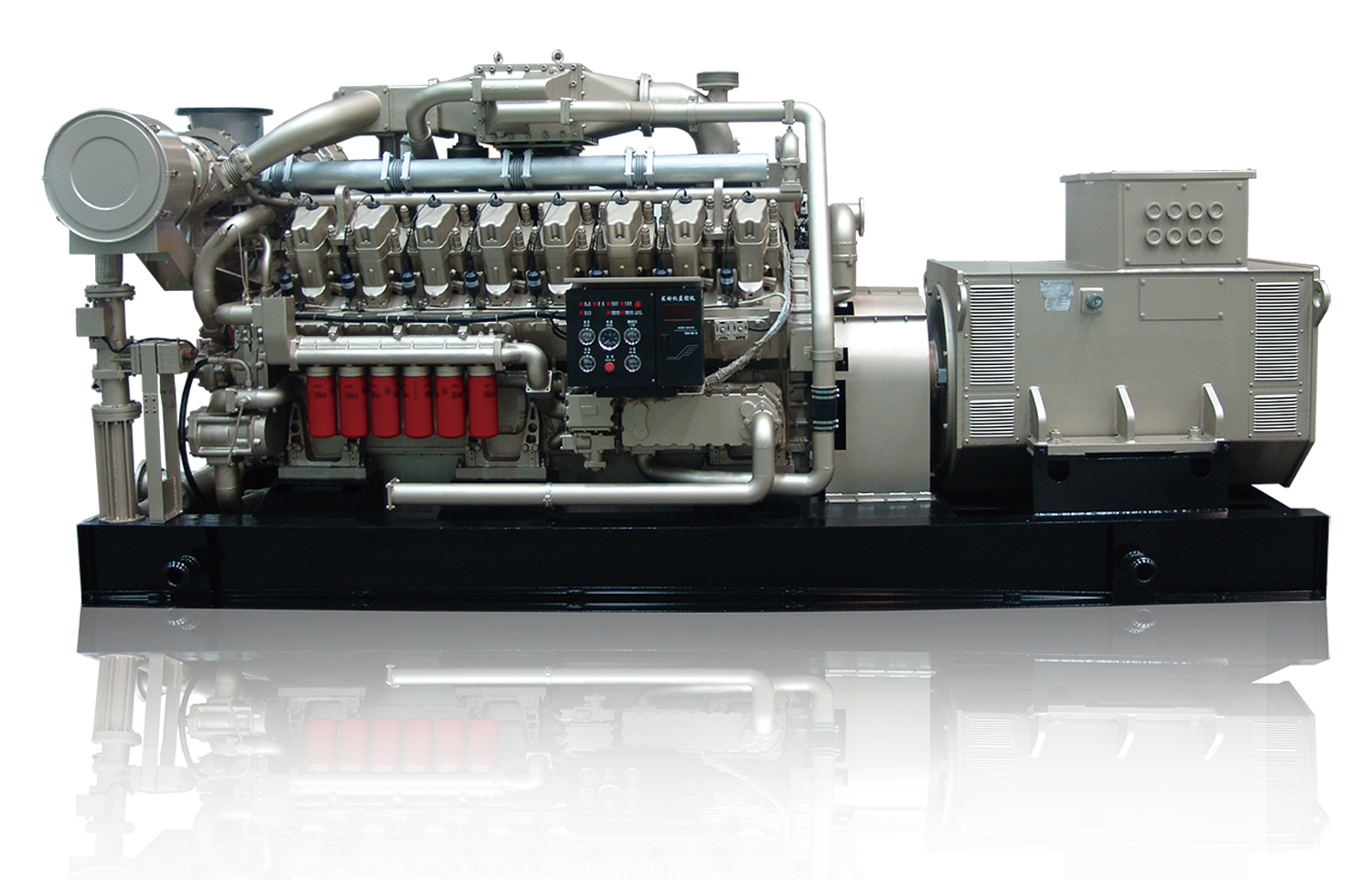

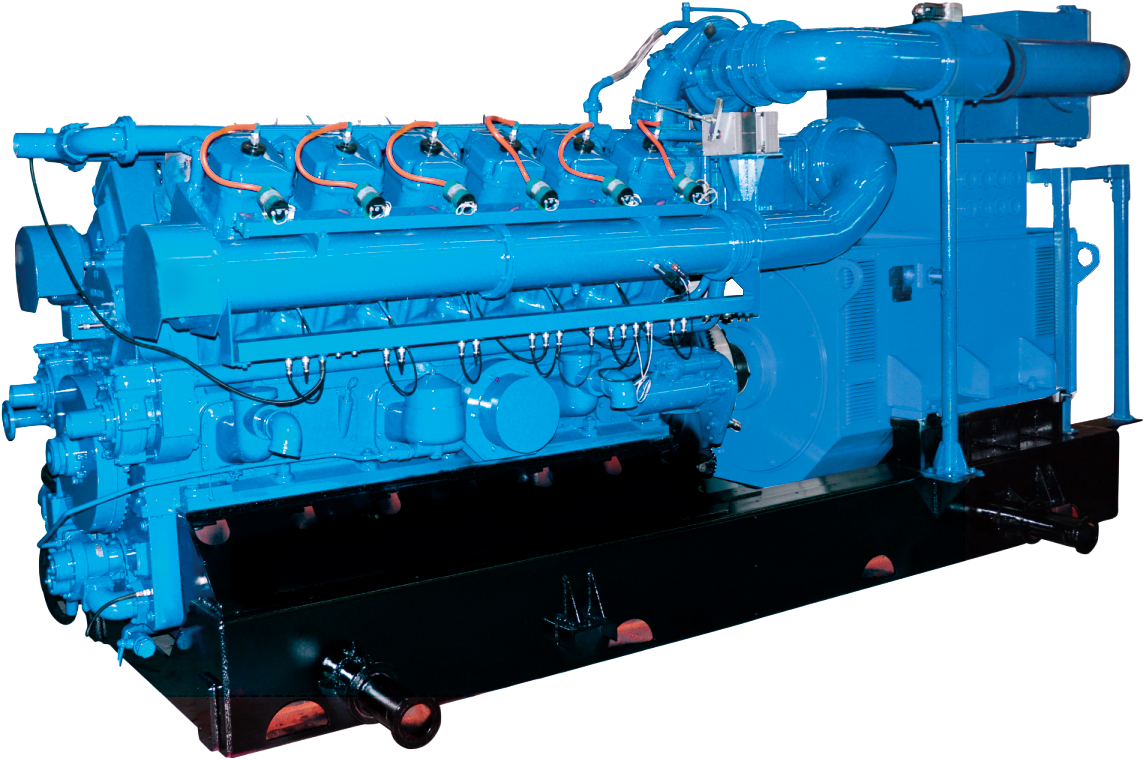

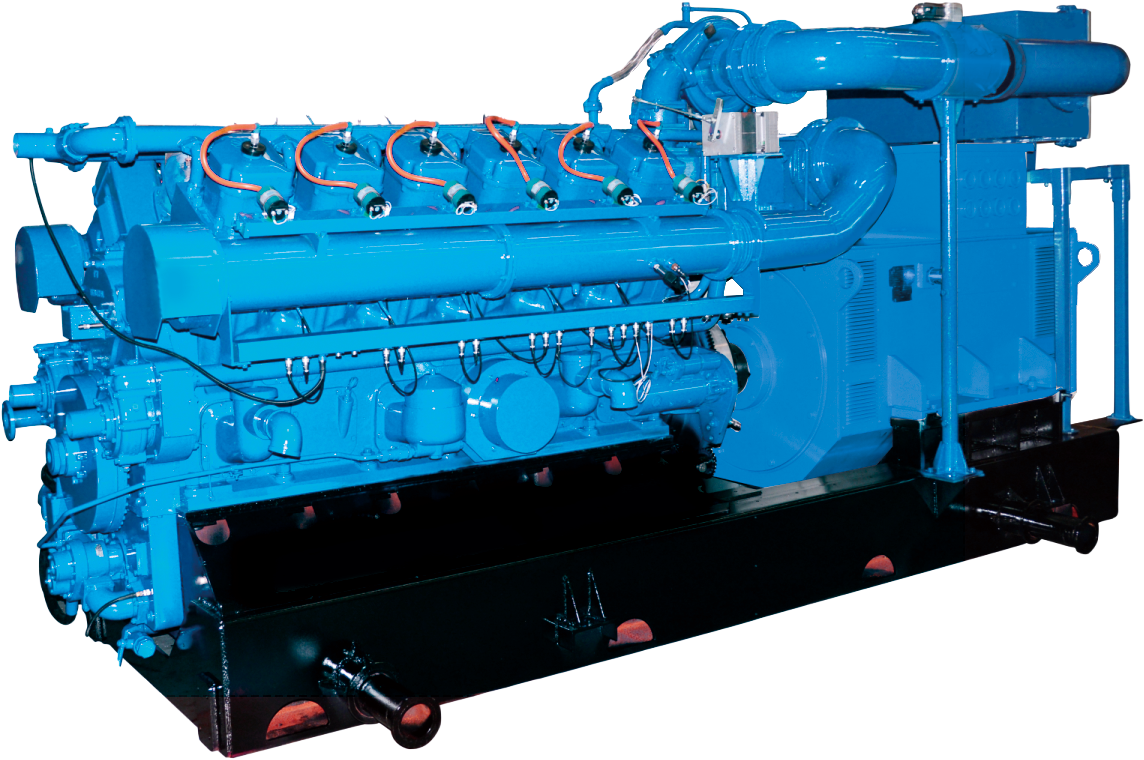

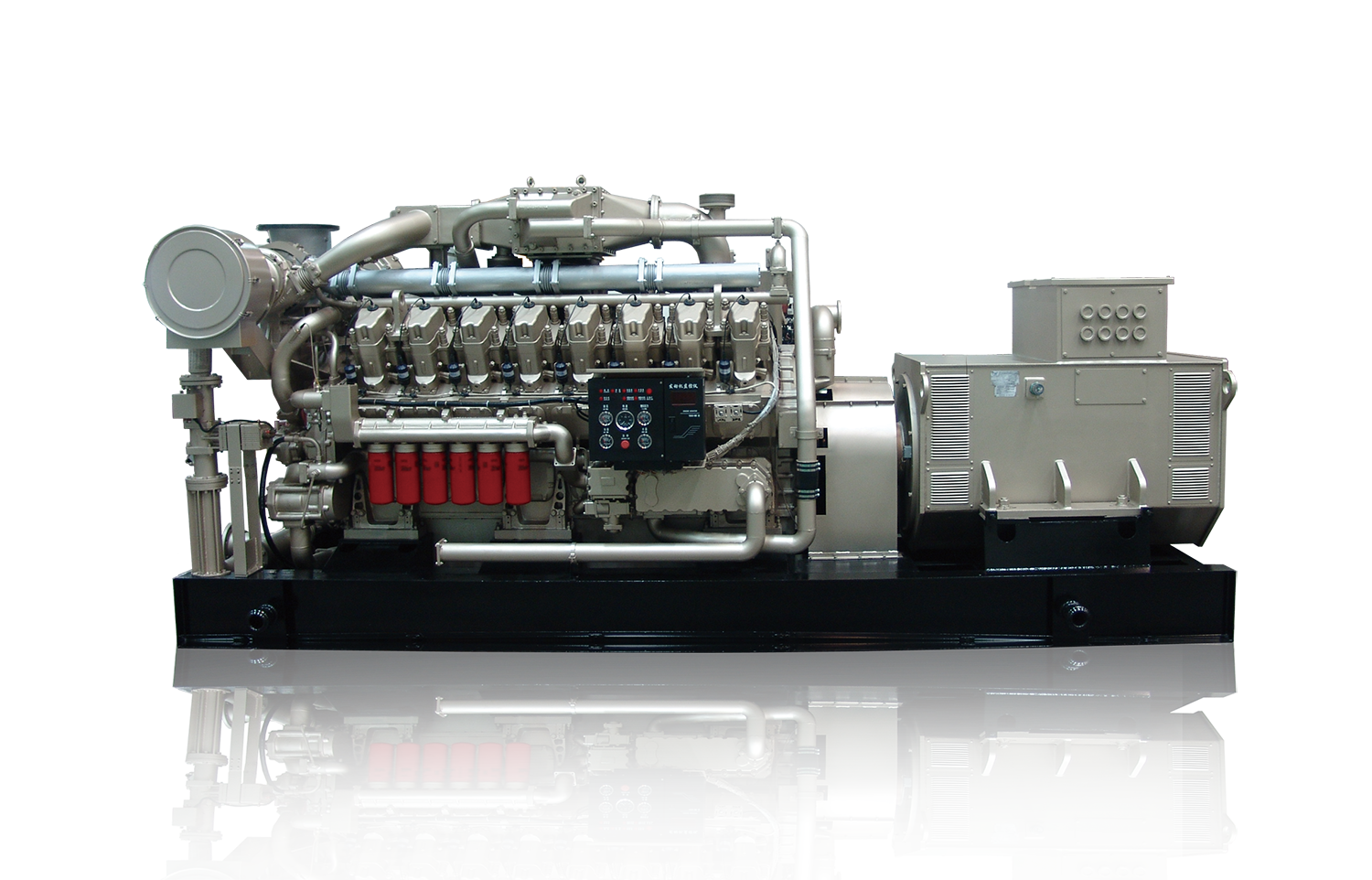

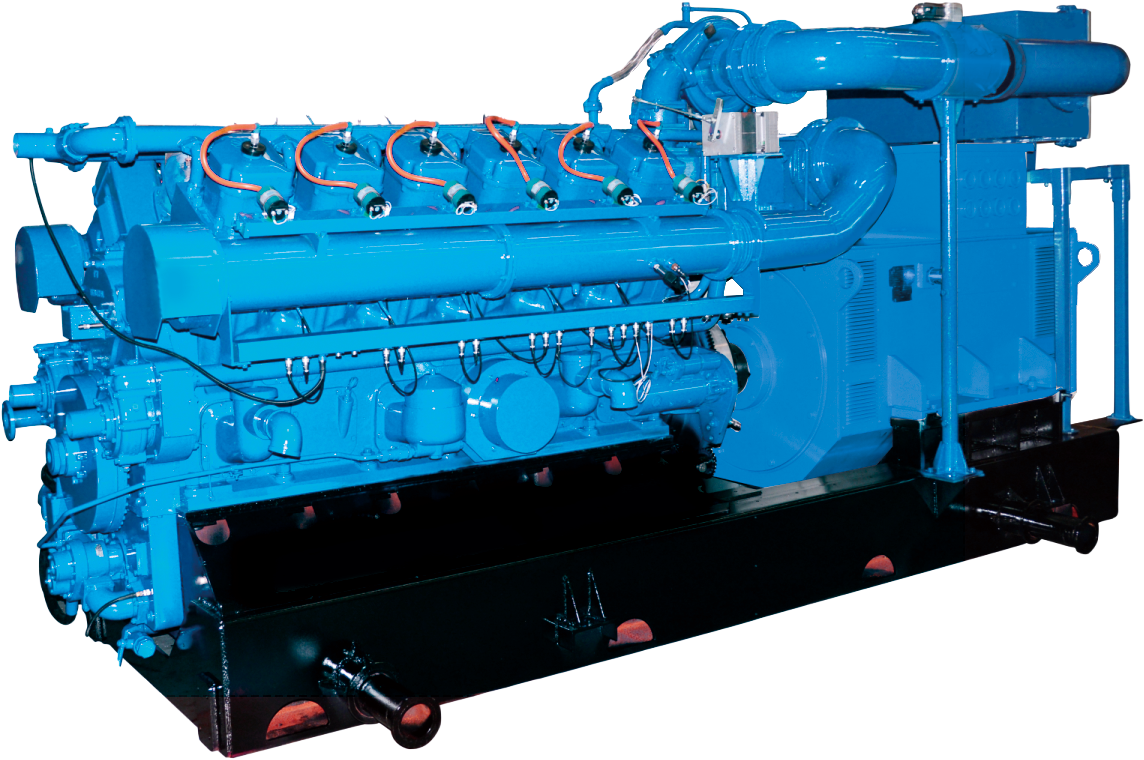

Power generation characteristics of high hydrogen generator unit flue gas purification equipment

The working principle of the flue gas denitration system is that the urea solution is decomposed into ammonia (NH3) and water (H2O) when encountering high temperature flue gas in the mixing zone of the exhaust pipe. After fully mixing with the flue gas, it enters the catalyst module, where NH3 and NOx react to generate harmless nitrogen (N2) and water (H2O), which are discharged through the exhaust pipe to meet the standard.

The urea solution is decomposed as follows:

Urea is pyrolysed and hydrolyzed to produce ammonia gas, which provides raw materials for the reaction.

Characteristics of pure SCR denitrification system

The flue gas denitrification system has high purification efficiency and meets the purification requirements of the Bidder for equipment;

Suitable for a wide range of temperatures, and can maintain good activity in the treatment temperature range of 400 to 550 ℃;

Low SO2 conversion rate and low production of NH4HSO4 (ABS);

Accurate urea solution calculation and control, high-precision metering and injection system, low operating cost;

The back pressure of the flue gas denitrification system is small, reducing the impact on the power of the natural gas generator unit;

The installation position of the denitrification system is reasonable, with a small floor area, and convenient maintenance and repair;

Performance characteristics of dedicated denitrification catalysts for internal combustion engines:

High activity catalyst: The porous structure provides a large internal surface area for the catalyst, providing a large number of active sites, ensuring high activity of the catalyst.

Very high anti toxicity: The optimized porous structure allows the catalyst to absorb large amounts of toxins without causing a decrease in activity.

High resistance to thermal and mechanical shock: The fiber strengthening of the catalyst provides structural flexibility and high resistance to thermal shock. The catalyst can operate under any normal load on the bench;

While meeting the denitrification efficiency required by the bidding document, it can effectively prevent carbon smoke particles from sticking, blocking, and poisoning in the catalyst;

The chemical life of the catalyst is 20000 hours, with a warranty of 16000 hours;

The catalyst design considers any trace elements contained in the fuel that may cause catalyst poisoning;

Before adding a new catalyst, the catalyst volume should meet the requirements for denitrification efficiency and ammonia escape in the performance guarantee.

With the summary above for hydrogen production tail gas generator units, I hope it can be helpful to our customers. If you have any questions or need help, please click on our website: Or call for consultation, and we will do our best to solve it for you

Tel:0531-69953988

Tel:0531-69953988  Add:101, Building 5, Liandong U Valley Science and Technology Innovation Center, Zhangjin Comprehensive Bonded Zone, No. 33688 Jingshi East Road, Suncun Street, Jinan Area, China (Shandong) Pilot Free Trade Zone

Add:101, Building 5, Liandong U Valley Science and Technology Innovation Center, Zhangjin Comprehensive Bonded Zone, No. 33688 Jingshi East Road, Suncun Street, Jinan Area, China (Shandong) Pilot Free Trade Zone